Winvic has once again secured Innovate UK funding as part of a cross-sector multidisciplinary research group. Winvic, University of the West of England (UWE Bristol), Edgetrix Ltd and Costain make up the consortium that will use the £800,000 funding to develop the first embodied carbon analytics AI system of its kind over the next two years.

The project entitled ‘AI System for Predicting Embodied Carbon in Construction’ (ASPEC) will predict the carbon output on building and infrastructure projects based on BIM designs, materials carbon data and lessons learnt on past projects. Its aim is in line with article eight – Carbon Capture – on the government’s 10 Point Plan for a green industrial revolution, which was launched last week.

While construction organisations continue to make advances in how they address both embodied and operational carbon emissions, current calculation methods for the former are onerous; with no design support calculation solution, there is no efficient way for design teams to proactively drive down the embodied carbon and carbon footprint of projects. The revolutionary technology will therefore be crucial in propelling constructors and material manufacturing firms to meet the UK government target removing 10MT of carbon dioxide by 2030. Furthermore, a 50 per cent reduction in carbon emissions has been set through the Construction 2025 strategy and the target for 2050 is to bring all greenhouse gas emissions to net zero.

In the UK alone, building stocks are responsible for 40 per cent of the UK’s total greenhouse gas emissions (UKGBC, 2020)

Buildings and construction together account for 36 per cent of global final energy use and 39 per cent of energy-related carbon dioxide (CO2) emissions (UNEP, 2018)

The proposed ASPEC therefore has three components, to meet the tangible needs of the industry:

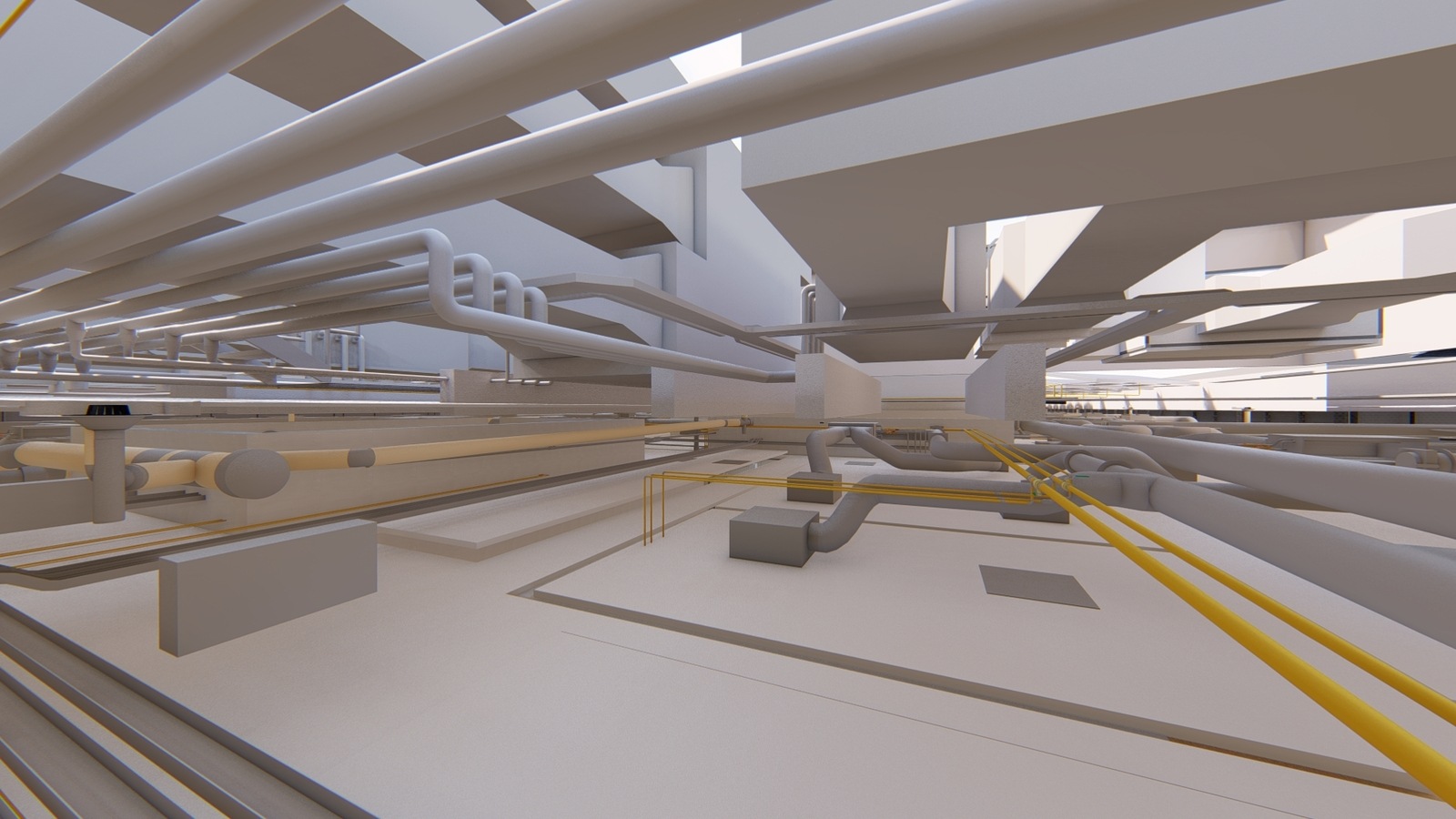

- AI-based Embodied Carbon Calculator (ECC) – This system will predict the embodied carbon cost of any project from a scheme’s BIM model. It will use historic embodied carbon data from previous construction projects and accurate ‘carbon factors’ to develop machine learning models. The creation of the ECC will lead to a dramatic reduction in the time it takes to calculate embodied carbon, bringing the process down from potentially days and weeks of data collection and calculation to a matter of a few hours.

- Embodied Carbon Analytics and Simulation Platform (ECAS) – This cloud-platform will undertake what-if analyses of the embodied carbon of schemes during the design phase. The tool will use advanced big data analytics to identify alternative design specifications that would reduce the embodied carbon of a project. A user of ECAS will be able to simply change the selection of a building material and obtain an instantaneous embodied carbon figure.

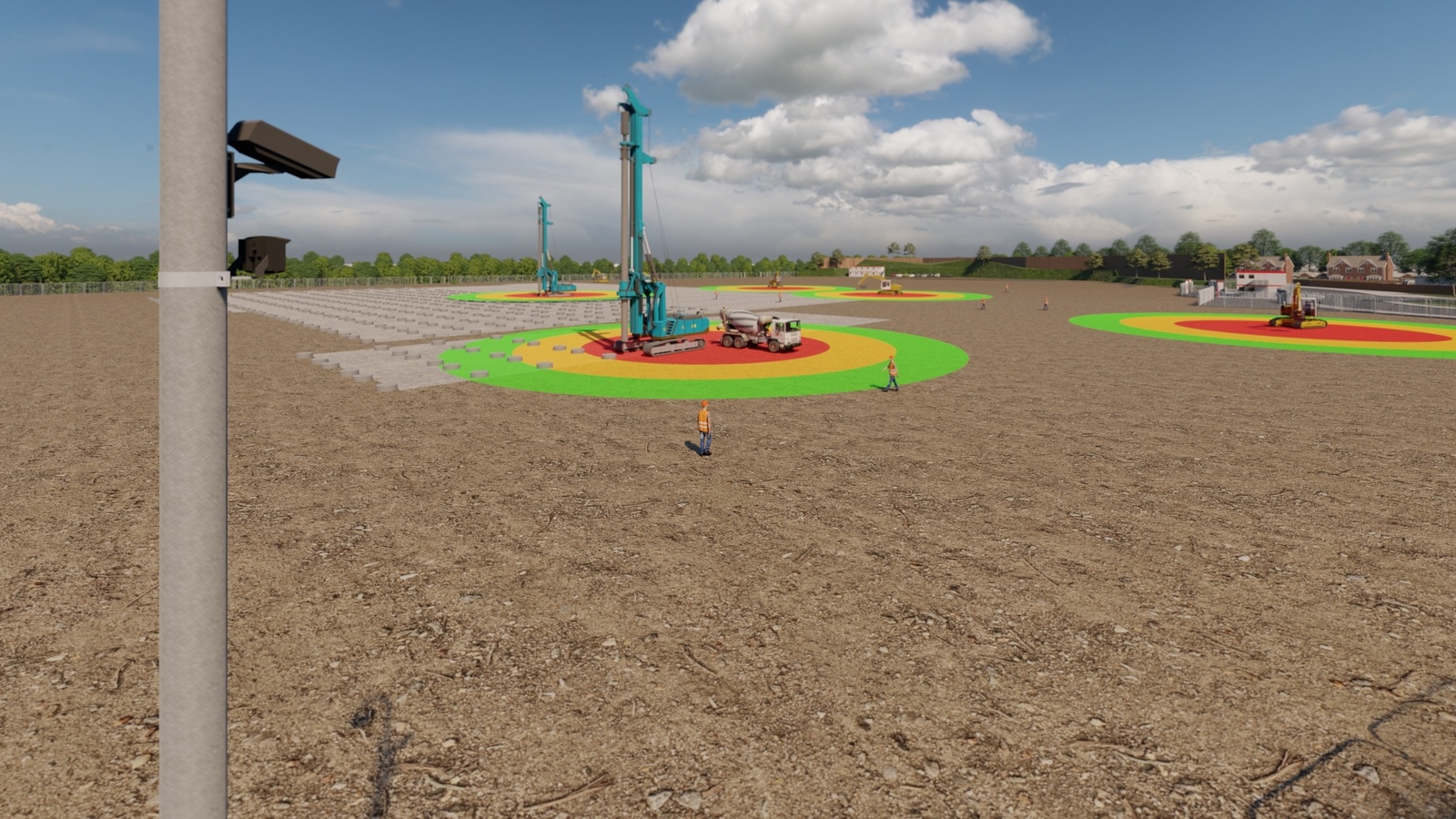

- BIM-based Design Support Tool for Embodied Carbon Analytics (B-DST) – This solution will also support design teams during the design stages of construction projects. It will integrate with existing BIM development software via an Application Programming Interface (API).

Tim Reeve, Winvic’s Technical Director and project lead, commented: “Following the announcement of government targets paired with BREEAM sustainability requirements, construction organisations and clients have worked hard to reduce emissions, but the task certainly isn’t simple. That’s why we believe that utilising the most up-to-date AI and advanced big data analytics techniques in a way that has never been done before will be transformational for Winvic’s green agenda and pave the way for significant changes across the whole industry. Having the ability to optimise schemes and see embodied carbon costs as real-time design and material changes are applied will naturally lead to quantifiable reductions in greenhouse gas emissions, and having technology that automatically estimates the embodied carbon cost of any digitally designed project will make the delivery of many project tasks much faster. It’s very exciting to be working on ASPEC – our third Innovate UK funded initiative – with Costain, UWE and Edgetrix and together we aim to deliver these two primary benefits of the project to the industry as early as Autumn 2022.”

Dr Lukman Akanbi, Associate Professor at UWE Bristol, said: “Through the ASPEC project, we as academics hope to contribute our technical know-how and expertise in Big Data Analytics and Artificial Intelligence to help move the UK one-step closer towards the realisation of her clean growth strategy and 2050 net-zero carbon target. In addition, UWE Bristol is a university that’s environmentally aware and is aiming to be carbon neutral by 2030, so it’s great that we are taking a lead in a project that is looking to help achieve these aims.”

Muktar Tijani at Edgetrix, commented: “This ASPEC project provides a simpler, more accurate and innovative approach to predicting embodied carbon in construction projects. As a rapidly growing construction tech-company, Edgetrix is delighted to be part of this project and are committed to helping organisations commence their Net-Zero journey through our expertise in carbon-cutting and modern tech-solutions”.

Crucially, Winvic and its project partners will develop a Common Data Environment (CDE) to eradicate the challenges that arise from having multiple, siloed datasets. The huge amounts of data that are generated from different phases of construction projects will be documented and stored in one system; it is this data nucleus that will facilitate the machine learning technologies, providing industry professionals with the insights to make more eco-friendly decisions on materials used.

For more information on Winvic, the company’s latest project news and job vacancies please visit www.winvic.co.uk. Join Winvic on social media – visit Twitter @WinvicLtd – and LinkedIn.

Share

Share

Repost

Repost

LinkedIn

LinkedIn

Email

Email