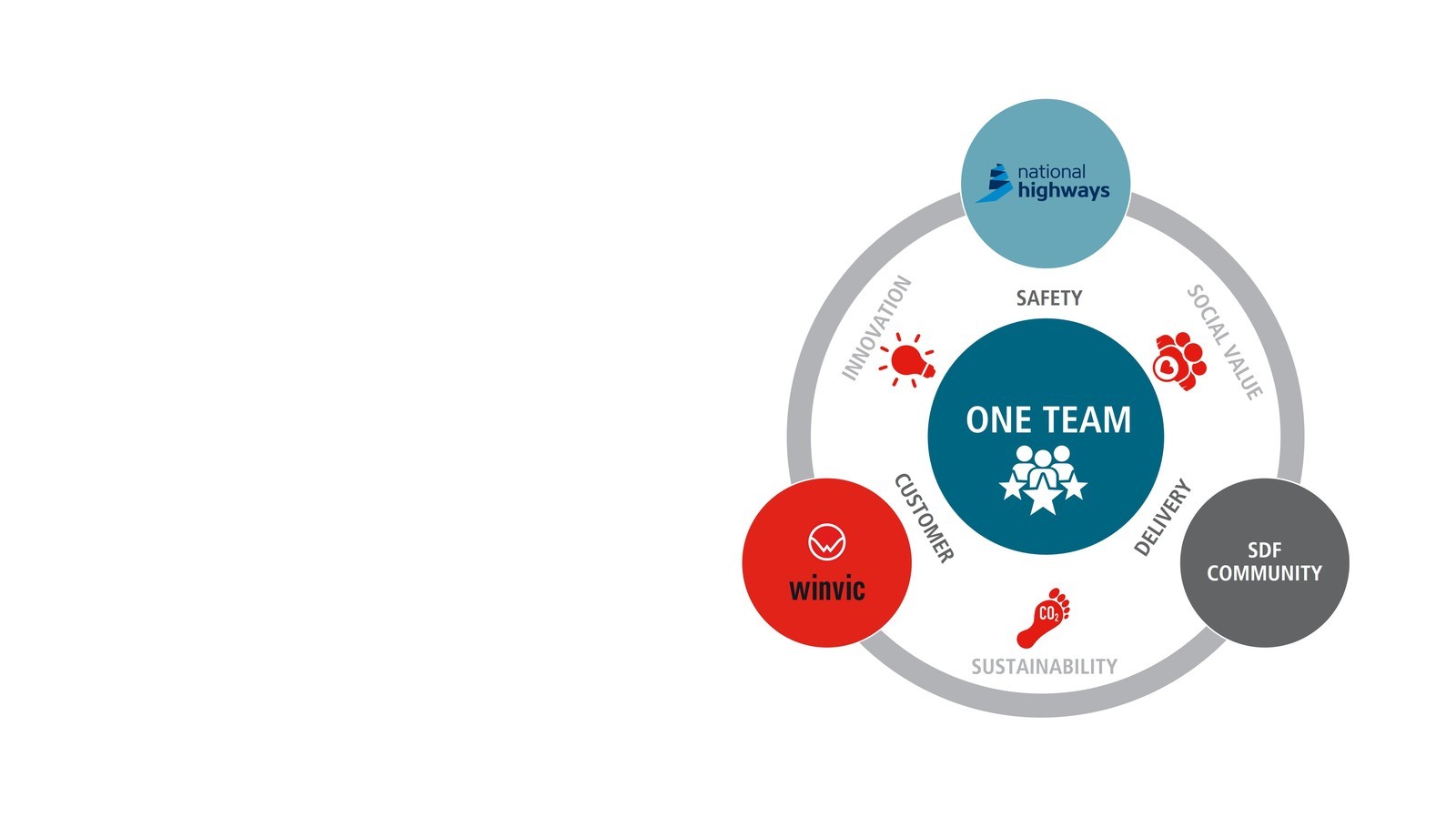

In 2021, Winvic was awarded two Lot contracts across four regions within the National Highways Scheme Delivery Framework (SDF) – Lot 8 – Structures, Waterproofing and

Expansion Joints, and Lot 10 – Structures, Structural Services and Concrete Repairs.

At a glance

- Project value: £900k

- Client: National Highways

- Engineer: WSP

- Programme: 22 weeks

- Completion: November 2024

- Framework

A404 Bisham Brook forms part of our Lot 10 works in Area 3 under the National Highways scheme delivery framework.

The Bisham Brook structure, built in 1972, comprises a corrugated steel buried pipe with a shallow concrete invert and entry points protected by concrete bag-work. It measures 61.010m in length and has a circular cross-section with a diameter of 3.658m. The corrugated steel is coated with bitumen for protection, initially applied during production and re-coated upon installation.

Routine inspections revealed signs of corrosion had occurred in parts of the structure, indicating that the structure was at risk of further corrosion and potential collapse.

This project aimed to address these issues and by re-applying the protective coating to prevent additional corrosion, as well as constructing in-situ concrete protection and installing new gravel bed.

As the project lead, Winvic collaborated with several National Highways project partners, including WSP, providing expertise in design and buildability during the Early Contractor Involvement (ECI) phase.

The works included:

- Vegetation clearance to allow access

- Damming of the water either end of the culvert and diverting the flow

- Excavation of the existing gravel and silt that lies on the concrete invert slab

- Applying protective coating to the corrugated steel pipe

- Drilling of the existing corrugated culvert and fixing of bolts to form a tie-in for the new concrete

- Fix shuttering and pouring concrete to form protection upstands to both side walls

- Laying a Gravel bed to the invert of the culvert, including access and exit ramps

- Localised repairs to the bag-work to the upstream and downstream entry points

Dan Hawkes, Construction Assurance Manager for National Highways said: “The scope of the A404 Bisham Brook scheme was to extend the life of the culvert under the A404 by providing protection to the culvert with profiled cast-insitu concrete benches, constructed within the confines of the culvert and a waterproofing coating applied.

The challenges were not confined to just the management of the stream that had be diverted via carrier pipes with pumps operating 24/7, but other sensitive environmental considerations to ensure the Environment Agency were comfortable with what was being undertaken, whilst protecting the natural habitats.

Despite the challenges experienced with the water ingress from anchor bolts drilled into the culvert lining and careful consideration of the adjacent residents, Winvic overcame this with a great level of professionalism and commitment to successfully deliver the works to a high standard.”

-

National Highways Scheme Delivery Framework

-

4,636 kgCO2e Carbon Reduction

-

Collaborative working

Considering Customer Needs During ECI

During ECI, we prioritised proactive engagement with key stakeholders, including local residents and the Local Authority, due to the need to close a local authority road near residential properties. Winvic actively contributed to the scheme communication plan, led by National Highways, ensuring effective stakeholder engagement. With customer and community impact in mind, we accelerated the programme by implementing six-day working, minimising disruption to local residents.

To further reduce the impact on the surrounding area, custom towable welfare facilities and track mats for site access were installed, to minimise disruption to the works, reduce environmental impact and preserve the landscape.

As well as this, an electric excavator and dumper were utilised within the culvert to eliminate exhaust emissions and contribute to the project’s carbon reduction goals, saving 4,636 kgCO2e.

Share this project:

Share

Share

Repost

Repost

LinkedIn

LinkedIn

Email

Email