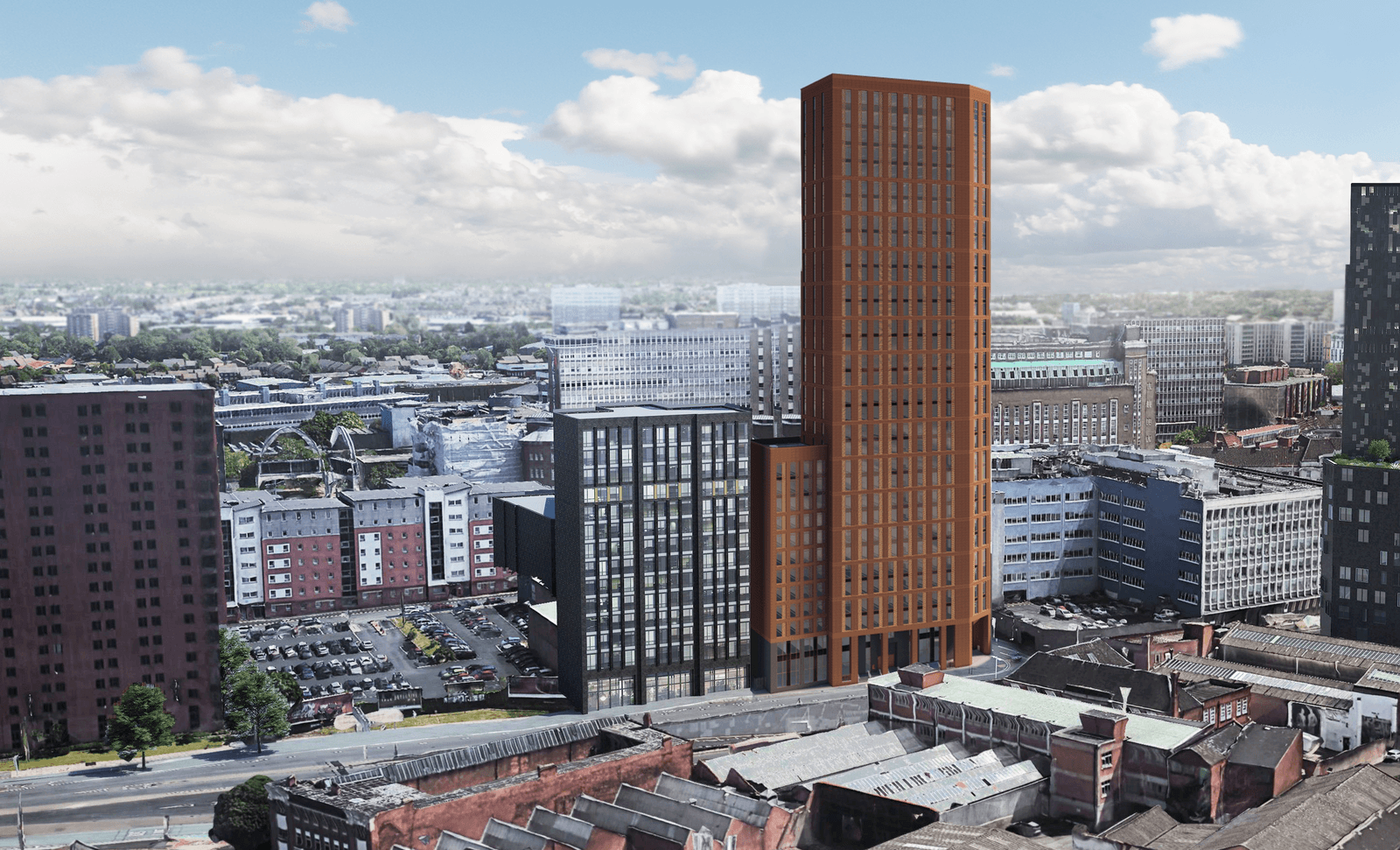

Winvic has been appointed to construct a 33 storey Purpose Built Student Accommodation (PBSA) building by Crown Student Living.

At a glance

- Client: Crown Student Living

- Architect: ECE Westworks

- Engineer: Meinhardt

- Programme: 153 Weeks

- Completion: Dec 2025 (Targeted)

The scheme consists of 814 bed spaces, in a mixture of 572 studios, 114 cluster flats, and 128 duplex rooms on the corner of Lancaster Street in Birmingham City Centre.

The building is a 33 storey tower with 9 and 12 storey ‘shoulder’ blocks to the sides and associated external works, including a 700 sq ft external terrace at first floor level. The scheme will also have three blue roofs at different levels and a green roof on the 33rd floor.

Internally, there will be over 13,000 sq ft of amenity spaces for the students, including communal kitchens, study rooms, dining rooms, lounge areas, a games lounge, cinema and a gym.

The structural frame is insitu reinforced concrete and the façade of the tower is to be constructed in a unitised brick façade from Level 2 to 32 with traditional brickwork to the lower two storeys. With just one metre of space on two sides and only 35mm between the building and its boundary on the other two, a factory-manufactured unitised façade was chosen to eliminate the need for scaffolding. This system allows for the rapid installation of 2,768 external wall panels, each prefinished with windows and brickwork.

Skyline Cockpit

Winvic is leading innovation in the construction industry as the first UK contractor to use a remote tower crane. Skyline Cockpit operates as a command-and-control centre, enabling remote operation of the tower crane from a ground-level cabin located on-site. The cabin is equipped with kitchenette and welfare facilities, significantly enhancing the physical working environment for crane operators.

The Skyline Cockpit promptly identifies any tower crane issues, enabling preventative maintenance measures. The military-grade cameras enhance crane efficiency by 25% and potentially reduce project completion time by an average of 8%, resulting in significant cost savings.

The crane can climb throughout construction to a maximum height of 102 metres, but the operatives don’t have to climb the mast to the control cabin. Instead, they enter a ground floor cabin containing 2.1 by 1.2 metre panoramic screens, which shows simultaneous views from seven cameras placed on the crane as well as a combined camera panoramic view providing better all-round visibility and eliminating blind spots. They also use Augmented Reality (AR) to display the load line, expected landing spot, as well as real-time indicators including wind speed, slew, lifting, hoist, jib, and radius data.

To see Skyline Cockpit in action and to hear from one of our crane operatives, watch the television news report from BBC Midlands Today over on our LinkedIn page.

-

814 student beds

-

33 storeys

-

Unitised Façade

Leading the way in innovation

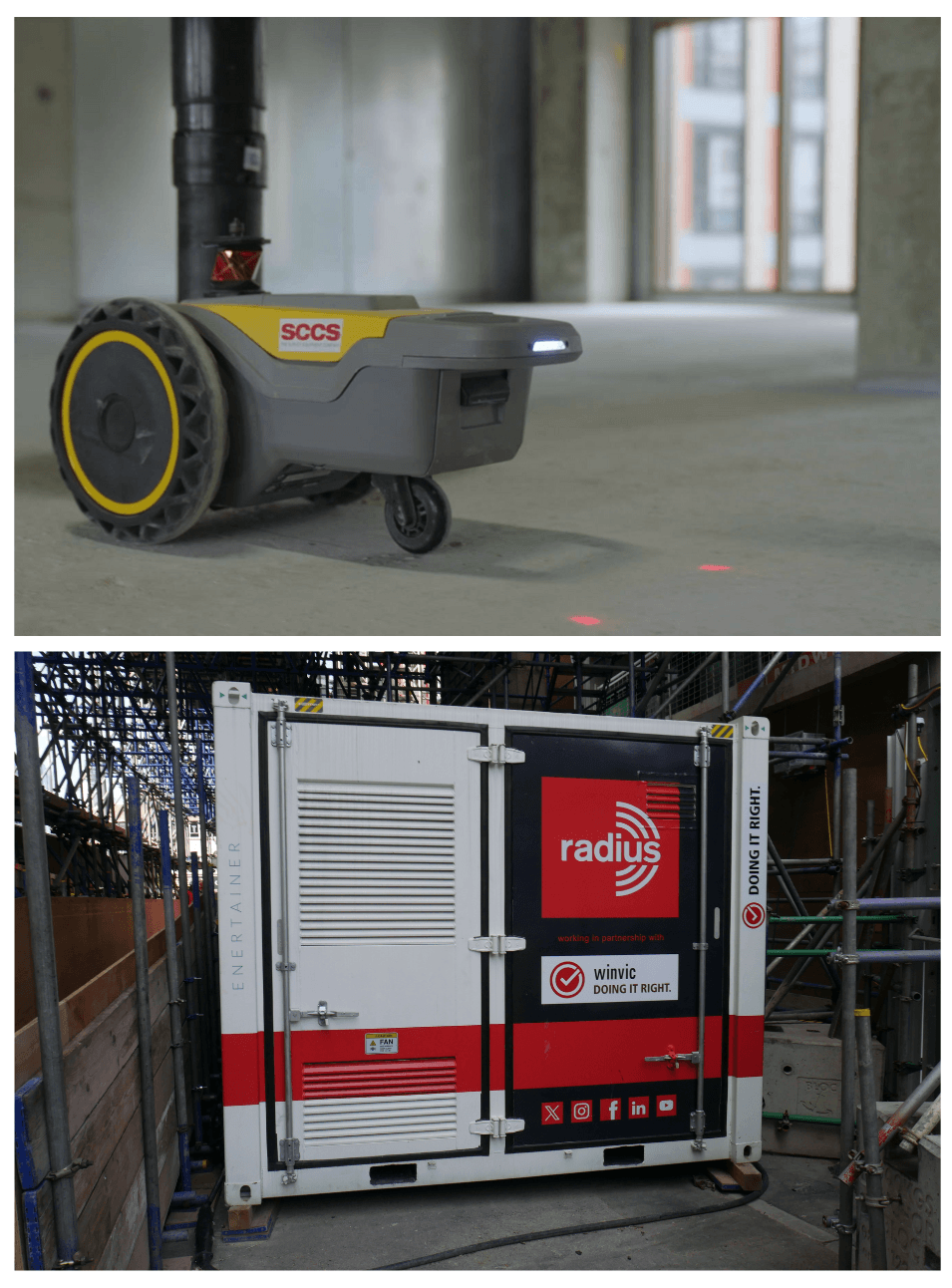

In February 2024, Winvic began using HP SitePrint, which is a BIM linked setting-out robot that prints a fully coordinated floorplan for 10 different subcontractors. Our site engineers and subcontractor teams no longer need to set out packages of work with traditional measuring and chalkline methods. Instead, the HP SitePrint robot travels around and prints all the required marks for all the ongoing trades, including packages of work that could not be previously marked on the floor slab, due to the time it would take.

22,000 sq m of coordinated floorplans will be printed in total over 32 floors at Crown Place Birmingham, three times faster than traditional manual techniques. The project was also selected as a test centre by HP, meaning Winvic were the first contractor to use the next generation robot.

At Crown Place Birmingham – and soon to be found on other Winvic projects – the AmpD Enertainer and its up-to-the-minute Lithium-Ion battery technology provides an uninterrupted power supply to the whole site. Connected to the mains electricity supply, the battery system is trickle charged 24-hours a day, converting 40 amps of power into 900 amps when required. For example, every time the hoist or crane commences operation, the unit provides the necessary power by utilising its stored energy. Any time the electricity load demand is lower, the stored energy is replenished.

AmpD Enertainer negates the use of circa 3,000 to 6,000 litres of diesel per week at Crown Place Birmingham, plus it’s almost silent, it removes the risk of fuel spillages, and is better for air quality, meaning the workforce and local communities directly benefit.

Share this project:

Share

Share

Repost

Repost

LinkedIn

LinkedIn

Email

Email