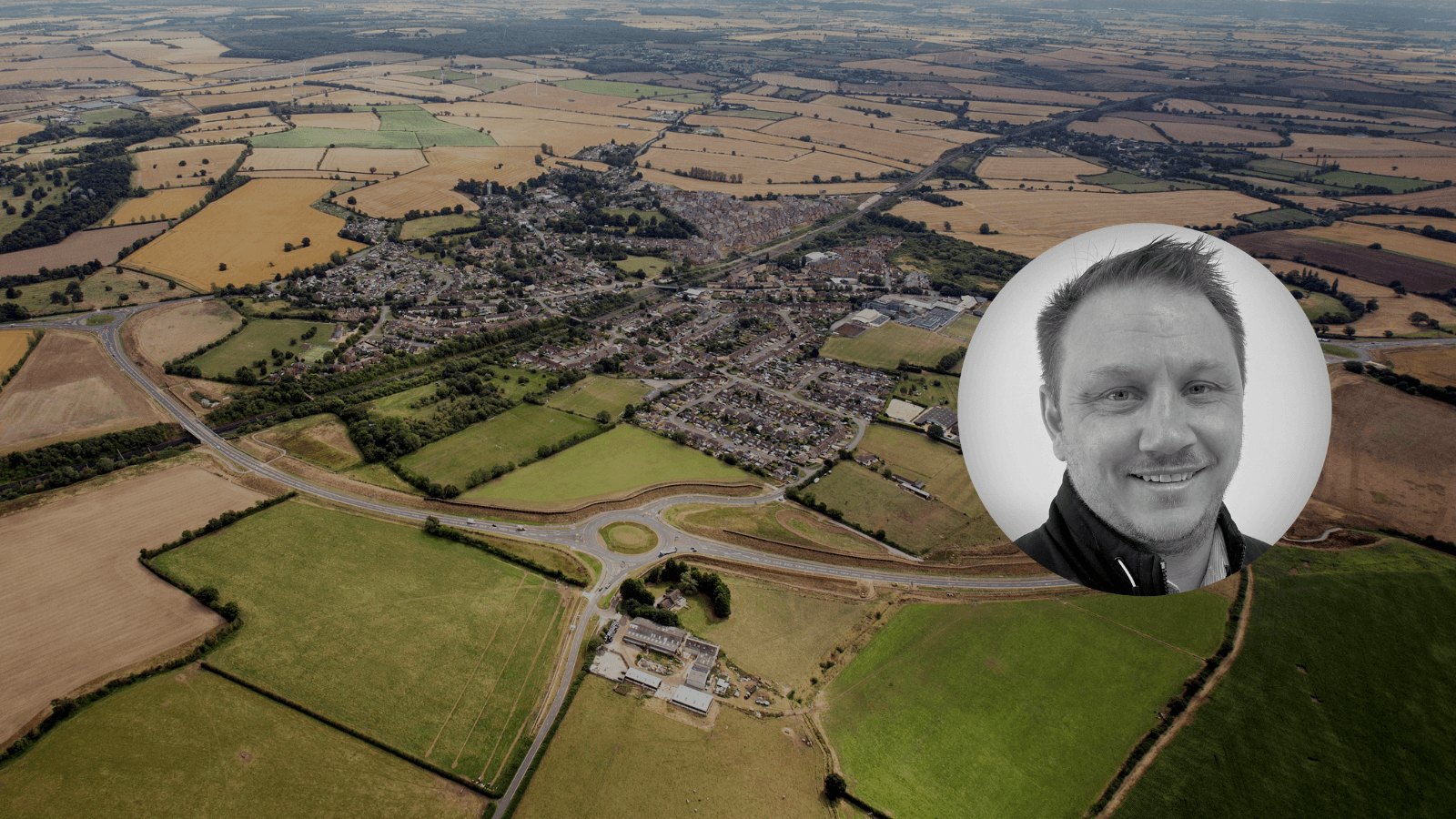

It’s one year since Roade bypass in Northampton opened to the public and the Project Director on the scheme – Scott Martin – has just been promoted to Contracts Director in our Civils and Infrastructure team. Therefore, we thought it was the perfect time to sit down with Scott and ask him to reflect on his 30-year career as well as the construction of the 2.5km bypass around the village of Roade, Northampton, which formed part of the SEGRO Logistics Park Northampton (SLPN) project.

What was your role at SEGRO Logistics Park Northampton?

The project comprised numerous elements, several stakeholder organisations and many moving parts so Winvic appointed me as the project director to support the project managers. There was an enormous amount of multi-organisational interfacing, detailed programming, risk and safety management and compliance to adhere to – and on top of that the project is Net Zero Carbon in Construction – so I managed a lot of the forward planning to enable the project managers to better focus on the more immediate activities. While processes are incredibly important, we’re very much delivery focused at Winvic. The scheme can certainly be described as a large-scale delivery, so the sizeable and very experienced team reflected the complex requirements to get things done and ensure they were done right. Additionally, it has created valuable opportunities to develop the next generation of construction professionals—something I’m particularly passionate about. Throughout the project, we’ve supported apprentices, work experience students and year in industry placements. I’d like to take this opportunity to congratulate one team member, Ammara, who has recently been announced as a finalist in the Highways UK Excellence Awards, in the Associate Laureates (Rising Star) category.

SLPN was designated as a Nationally Significant Infrastructure Project (NSIP) and has a Development Consent Order (DCO) permitting development of up to 5 million sq ft of distribution buildings as well as a 35-acre Strategic Rail Freight Interchange (SRFI). To ensure the surrounding highways network could handle the additional traffic from the development, we also delivered a major reconfiguration of junction 15 of the M1, significant improvements at junction 15A and the 2.5km bypass of the A508 that goes through the village of Roade.

Tell us about the Roade bypass programme?

It’s a 2.5km single carriageway with three new 60 metre diameter roundabouts, which tie into the A508 between Milton Keynes and Northampton, which previously went through Roade village. The new carriageway traversed an existing bridleway, so we also had to construct a steel arch underpass, and also the rail tracks of the West Coast Mainline (WCML), meaning a bridge was required.

The 48-metre span composite bridge was the most complex and unusual element because its location, in a Victorian rail cutting, is extremely delicate and designated a Site of Special Scientific Interest (SSSI). The design, with abutments set further back, ensured efficient loadings and no force on the cutting, and we protected the heritage of the area throughout construction by using inclinometers to measure any movement in real time. As you would expect, collaboration and derisking activity with Network Rail (NR) began over a year before the bridge works commenced. In this Early Contractor Involvement (ECI) period we achieved early design approvals, completed lifting plans and procured all materials and plant. We also explored the different rail possession options available and put plans in place. Our meticulous upfront work ultimately resulted in no rail passengers being inconvenienced, us meeting all deadlines and all quality compliance certificates being secured.

Were the bypass carriageway and roundabouts without challenges?

Absolutely not, and as with the bridge – or any other highways project – there was a balance to be struck between safety, programme, negating public disruption and cost, plus the Net Zero requirements. To help reduce the project’s embodied carbon, we compared traditional all-bituminous materials compared against layered options and constructed the carriageway in five layers comprising CBGM, Warmix base/binder courses and an SMA surface course. Not only was this a sustainable option but it provides better lifelong value and reduces road noise.

Stakeholder liaison, once again, was crucial and we applied our ‘one-team, one goal’ approach, working with West Northamptonshire Council’s highways department and National Highways. We undertook network occupancy reviews, road space booking analyses and traffic management modelling to ensure the best outcomes and that other diversion routes wouldn’t be affected. The road between Roade and another village, Blisworth, was closed for six weeks and the rest of the works were undertaken under two or three-way traffic management, apart from the final roundabout tie ins which required short weekend closures.

There was of course significant liaison with planning, SEGRO’s land agents and the landowners too, of which there were six. The land itself comprised both livestock and arable farming land so in the initial phase there was testing of top and sub soils, which informed the design. Landowner collaboration continued throughout, and we worked with them – and their preferred contractors – to ensure cattle fencing met their requirements. Regular interfaces were also held with 10 statutory undertakers in total, which included the programming of 3km of service diversions.

This number of diversions was obviously a complex part of the programme, and also several unmapped underground services were found upon excavation, including a 400ml water main. However, the relationships we had built through ECI alongside our expert programme management allowed us to redesign and gain approvals quickly to remain on schedule.

The other major challenge was a 4-metre differential in ground levels at two of the roundabouts – the Blisworth Rd roundabout required a 4-metre cut and the Stratford Road roundabout a 4-metre fill. We utilised digital modelling – Building Information Modelling (BIM) – to undertake vertical alignment and construction thickness modelling and then used innovative semi-automated GPS-enabled construction plant to ensure excavations were at the at correct depth and deposition height.

Have highway and bridges featured throughout your career?

Yes, and I actually started out as a Civil Engineering Apprentice in Lincoln City Council’s highways department in September 1994, so it’s probably 30 years ago to the week! It was quite hands on, and I worked through the different departments learning design and construction from highways and bridge engineers and by visiting sites through their direct labour organisation. I moved to Lincolnshire County Council (LCC) highways department next as a technician on the design and engineering of new and existing carriageways and structures and I also spent time in the materials testing laboratory. In my new role I’m responsible for Winvic’s highways framework contract with LCC, amongst others, so I’ve recently been thinking about this time in my life. It was when I started to go out and supervise the construction of some of the bridge and culvert designs that I’d worked on that I found my calling and realised that I enjoyed the cut and thrust of being out on site more than design. Since then, I’ve worked for different contractors as a site agent, senior site agent, project manager and contract manager delivering new highways and bridges as well as some other interesting infrastructure projects. I became a part of the Winvic team in January 2021 and haven’t looked back – it’s been an incredible journey, and I’ve enjoyed every day since.

What projects stand out in your career?

In a similar way to how the Roade bypass and motorway junction improvements help to facilitate SLPN, I worked on an 18-month long scheme to support the development of Babraham Research Campus with the realignment of the A1307 in Cambridge. This was my first large project, and it comprised a lot of new onsite infrastructure. But I remember the excitement of working on the Nottingham train station extension and the onshore substation at Sizewell, which harnessed the power of 56 offshore wind turbines that were two miles off the east coast.

That one was fairly unusual but the project that stands out the most is repurposing British Steel’s old 36-metre-deep continuous casting shaft, which was the deepest in Europe whilst it was operating. We had to remove all the below ground level steel and construct a new working platform 26 metres above the base of the shaft to house a new Vacuum Induction Melting (VIM) furnace. Projects like that are once in a lifetime.

Now you’ve been promoted to Contracts Director, what projects will you work on?

I’m still overseeing the concluding earthworks and rail connections to the SRFI at SLPN, which is essentially the final configuration of the private SEGRO signalling and Network Rail’s signalling. I also mentioned the LCC framework and we’re now working on the third project that will utilise around 8,000 tonnes of material. It’s a five-month reconstruction of Dysart Road in Grantham, including the junctions of adjoining side roads, where we’re excavating and rebuilding the entire road in sections.

I’m also responsible for our other current highways frameworks and will look after any other similar contracts we’re awarded. For example, we have a place on the National Highways Scheme Delivery Framework (SDF), Warwickshire County Council’s (WCC) highways framework and Procure. Therefore, I’ll be involved with a multitude of projects but obviously with a reduced on-site day-to-day requirement to that of Project Director at SLPN.

While the cut and thrust of working out on site was a real driver for me, and I haven’t lost that love, over the years I’ve certainly found new passions, such as holistic management and stakeholder engagement which was an integral part of our collaborative approach at SLPN through the Community Liaison Group. This new chapter in my career is exciting and I’m ready for the challenge of growing our Civil and Infrastructure sector organically with the backing of the senior leadership team. Whether it’s targeting new business, liaising with clients, developing our people or supporting project teams, my aim is to uphold the Winvic Way core values and ensure that we’re always putting our best foot forward.

Share

Share

Repost

Repost

LinkedIn

LinkedIn

Email

Email