Technology & Innovation

THE FUTURE OF MODERN CONSTRUCTION

Our clients benefit from our tenacity to challenge industry norms and explore innovative products, methodologies and designs. Research and development is therefore crucial to Winvic and we are always working with key suppliers and consultant partners to progress ideas into manufactured articles. We understand that no two buildings are the same, so we take a customised approach to every corner of every project so that the right solution is applied systematically, effectively and to brief.

Nevertheless, we don’t shy away from offering up our pioneering ideas if there are gains to be made for the client or end user, because why wouldn’t we want to make a scheme the very best it can be. Some of our technological advancements include specialist ground solution techniques, carbon zero applications, creating our own revolutionary carbon calculator, building information modelling (BIM), renewable solutions and multiple Innovate UK projects. All of which is incorporated into a customised business information hub for our supply chain, design teams and clients to take advantage of.

With support, Winvic has developed revolutionary design advancements in multilevel mezzanine structures:

- Multilevel concrete mezzanine floors with complex design equations

- Optimum crack control and surface deflection tolerance

- We have led the debate for a more homogenous approach of all aspects of the design

- The whole industry is reacting to our approach and considerations

Our Commitment to BIM

Building Information Modelling, or BIM, is the process of design and construction – digitally, in 3D – which has a wide range of end-to-end benefits for the developer, tenant and the contractors involved. From cost savings and shorter construction programmes to faster design decisions and efficient building management, delivering industry standard BIM Level 2 is another example of Winvic doing it right.

We have offered this service to clients for many years, but over the last two to three years we have experienced a significant uptake in the request for BIM on the projects we are involved in. As a result of this growing demand, Winvic focused on creating a state-of-the-art resource, and the Centre for Innovative Construction (CIC) was launched during Digital Construction Week in October 2019. This was followed by the launch of onsite Sustainability & Innovation Hubs.

Read more about the benefits that digital design and BIM brings to our clients, end-users and workforce.

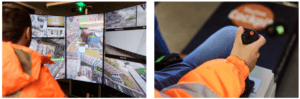

SKYLINE COCKPIT

Winvic is leading the industry with a UK first; using Skyline Cockpit – a pioneering technology that operates tower cranes from a ground control system.

Our commitment to health, safety and wellbeing were the drivers for us selecting a pioneering technology for use at the 33-storey Crown Place Birmingham project. However, the cutting-edge machinery also turns tower crane operation into specialist digital profession and we’re certain the innovation will attract many young people, especially gaming aficionados.

Skyline Cockpit allows tower crane operators to undertake the role from a ground control system, instead of first climbing up the mast section to the tower crane cab. Break times now don’t include a climb either as the ground control command centre also comprises kitchenette and welfare facilities.

The control centre is found inside a cabin on level one at the Purpose Built Student Accommodation (PBSA) project, which when complete will contain 814 student beds. The 2.1 by 1.2 metre screen shows simultaneous views from seven cameras that are placed on the crane as well as a combined camera panoramic view providing better all-round visibility and eliminating blind spots. Augmented Reality (AR) also display various data to the crane operator, such as the load line, expected landing spot, wind speed, radius data and more. The controls, safety and comfort aspects enhance the experience for the operator and also facilitate more efficient operations.

The 14-tonne capacity Potain MR225 crane with the Skyline Cockpit technology is being used to lift and distribute multiple materials, including unitised curtain walled façade panels and prefabricated bathroom pods. To see Skyline Cockpit in action and to hear from one of our crane operatives, watch the television news report from BBC Midlands Today over on our LinkedIn page.

HP SitePrint

In February 2024 we began using HP SitePrint, which is a BIM linked setting-out robot that prints a fully coordinated floorplan for 10 different subcontractors. Our site engineers and subcontractor teams no longer need to set out packages of work with traditional measuring and chalkline methods. Instead, the HP SitePrint robot travels around and prints all the required marks for all the ongoing trades, including packages of work that could not be previously marked on the floor slab, due to the time it would take.

22,000 sq m of coordinated floorplans will be printed in total over 32 floors at Crown Place Birmingham, three times faster than traditional manual techniques. The project was also selected as a test centre by HP, so we were the first to use the next generation robot.

GAMMA AR

We’ve also been using an Augmented Reality tool called GAMMA AR in Birmingham, which blends virtual designs with the physical as-built environment. Instead of overlaying 2D drawings and correlating multiple package designs with the delivered works as part of our quality assurance process, our team members can use the camera of a tablet to view the as-built environment and superimpose the Building Information Modelling (BIM) designs on the screen.

The 3D digital designs can be overlayed completely and in gradations of transparency, meaning the analysis between the design and operations outputs couldn’t be simpler. Should any design deviations be found, the operative can assign details there and then from the tablet and the package owner will receive an immediate alert. GAMMA AR not only speeds up the quality assurance process for Winvic site managers and site engineers, but it also provides a pre-installation visual reference and clients can use it to make faster design decisions.

AmpD Enertainer

At Crown Place Birmingham – and soon to be found on other Winvic projects – the AmpD Enertainer and its up-to-the-minute Lithium-Ion battery technology provides an uninterrupted power supply to the whole site. Connected to the mains electricity supply, the battery system is trickle charged 24-hours a day, converting 40 amps of power into 900 amps when required. For example, every time the hoist or crane commences operation, the unit provides the necessary power by utilising its stored energy. Any time the electricity load demand is lower, the stored energy is replenished.

AmpD Enertainer negates the use of circa 3,000 to 6,000 litres of diesel per week at Crown Place Birmingham, plus it’s almost silent, it removes the risk of fuel spillages, and is better for air quality, meaning the workforce and local communities directly benefit.